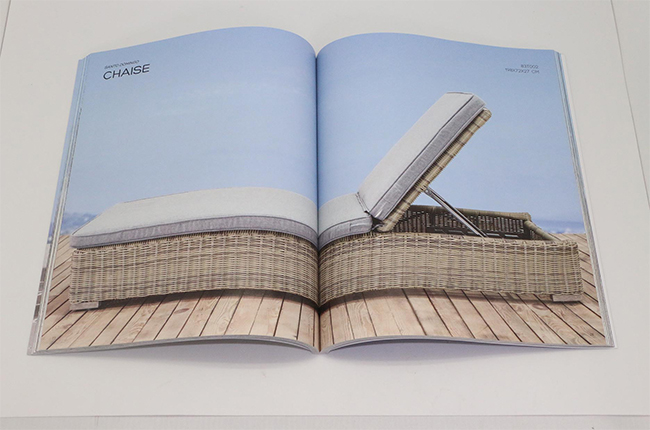

In GuangAo wholesale planner printing factory, the vast majority of printing a custom planner and other printed materials are from Heidelberg CD102 four-color printing machine. Heidelberg four-color offset press is characterized by fast printing speed, high precision of multi-color registration and stable performance. Custom printing planner pages, contact GuangAo.

However, many colleagues say that it is difficult to operate. They say that it has high requirements for the printing production environment. The power must be stable, the temperature and humidity should be moderate, the ventilation should be good, and the operation should be standardized. If it is not satisfactory, it will stop working.

In fact, according to the experience of GuangAo printing factory, in the actual printing planner pages production of Heidelberg CD102, as long as the operators have a strong sense of responsibility, they must strictly follow the operating procedures, and they can develop good operating habits in their daily work. Transfer Heidelberg CD102 four-color printing.

First of all, go to work every day to do the shift work, and do the preparations before the hardcover custom planner printing services, understand the running status and maintenance of the machine, whether there are any faults, etc., to ensure that the machine is in good technical condition.

Then check the job engineering sheet, read the weekly notebook printing requirements carefully, understand the printing order, enter the paper format size, thickness and other parameters. At this point, the old driver of the printing department will always remind everyone to pay attention to check the appearance of the printing plate and whether the layout is flat. , clean, wipe the glue evenly, no damage, no creases, no scratches, no dirt and ink spots, etc.

Then there is the plate-loading printing. According to the working regulations of Mida printing, the plate cylinder must be reset to zero, inking, printing and adjusting the printing sheet, checking whether it meets the job requirements, adjusting the ink and water, overprinting, and after checking that the printing meets the requirements, be sure to find a printing machine The minister and the quality department jointly proofread and sign the first sample. This action is what Mida hardcover printing must insist on doing.

Arrange for the crew to decontaminate and clean the tape, try running again, check the dirty spots, and arrange for decontamination after washing the tape, adjust the ink area through the CP window and console in time, adjust the planner printing ink color and compare it with the proofs. After cleaning the blanket, the master paper should be spared, and the official printing should be carried out when the blanket is clean.

Finally, pay attention to maintaining the balance of ink and water during the custom printing planner pages process. Ink and water balance is a state that changes at any time. How to maintain it is also introduced in detail in the previous article. Today, I will briefly summarize the method:

Printing Planner Pages Ink Balance

1. Maintain the temperature and humidity of the printing planner pages workshop, the temperature is kept at about 18-22 degrees Celsius, and the humidity is about 50-70%.

2. The printing speed is stable, according to the standard speed of Heidelberg, and there should be no excessive speed fluctuation.

3. As a Heidelberg CD102 captain, you must also have the ability to grasp the characteristics of paper. Different types of paper have different characteristics, bulk thickness and density, and the adaptability to ink will also be different.

4. The temperature and humidity of the workshop should be stable, because the change of temperature will cause changes in the viscosity and fluidity of the ink, and the increase of temperature will cause the water to evaporate, thus causing the ink to lose its balance. It is best to control the temperature within the range of 18°C to 22°C, and control the relative humidity within 50-70%.

5. The spiral planner printing speed should be stable. During production, the machine must run at a normal speed, and the machine can be fast or slow, which can easily make the ink-water balance out of control. Under the same conditions of printing plate, temperature, humidity, etc., it is necessary to grasp the change of their properties.

6. The use of drying oil should be appropriate, and the pressure adjustment should be accurate. Finally, the finishing work of printing should be handled according to the cleaning process and car washing operation specifications of Mida printing.

GuangAo Printing agrees with everyone to discuss and improve together on the work experience of custom agenda printing. We regularly organize internal printing technology training to give employees a systematic learning opportunity, reduce the quality accidents of hardcover book printing sheets, and provide customers with perfect hardcover planner printing works. direction of work effort. Come to GuangAo factory and teach you how to use Heidelberg CD102 four-color printing press